Our Capabilities

Experience, skills and a global footprint

Make your job easier!

KI is your sole source for multiple products, processes, and finishing technologies

OUR PROCESSES

- Injection Molding

- One-shot

- Two-shot

- Three-shot

- Gas Assist

- 60 – 1,200 ton machinery

- Chrome plating

- Die Casting

- PVD

- Gas Assist

- Painting

- Laser Etching

- Pad Printing

- Hot Stamping

- Powder Coating

OUR FINISHES

- Plating

- Bright Chrome

- Satin Chrome

- Bright Nickel

- Matte Nickel

- Brushed Stainless

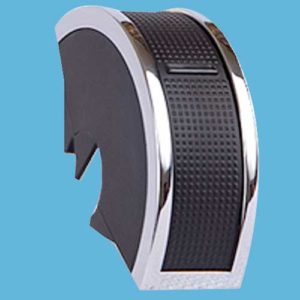

Custom Part Manufacturing

Your design ideas begin to come to life with our manufacturing processes. From gas assist molding, single shot, two shot, and three shot molding, as well as die-casting, laser etching, and In Mold Labeling (IML) we can be your one source for all of your production needs.

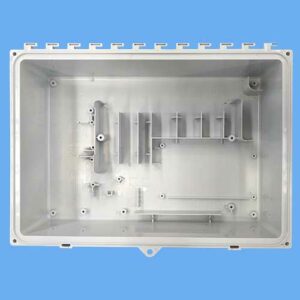

Injection Molding

Die Casting

Our die-casting experience is extensive and products can be produced with smooth or textured surfaces. KI also has the ability to apply a variety of painted, chrome plated or PVD finishes giving our customers unlimited design possibilities.

Mold Only

Whether your product designs are simple or complex, decorative or functional, our injection molding expertise will help bring your product to life! Take advantage of our successful experience manufacturing large tonnage, mold only

products.

IML/IMD

Decoration and Finishing

Complete your product with one of our high-quality finishes. Our capabilities include chrome plating, PVD, electroplating and PVD with selective brushing, painting, laser-etching, pad printing, hot stamping, silk screening and roll coating. Formed aluminum components with rotary spin finishing or micro-briting may also be used to enhance the appearance.

PVD

Get the look of chrome on plastic parts that can withstand higher temperatures than ABS based resins/blends. Finish colors can vary depending on the target materials used.

Graphics can be applied on the PVD surface for superior durability and performance characteristics compared to graphics printed on chrome plating.

Part Assembly

KI offers a flexible manufacturing environment tailored to your sub-assembly needs. We can assemble multiple components allowing for flexibility in part design to meet mechanical and functional requirements without sacrificing cost constraints or aesthetic quality.

Suppliers to the auto industry

We know everything when it comes to design reviews, manufacturing, and decorating parts, but without our clients we’d just be spinning our wheels.

We produce over 50 million various pieces and assemblies annually for the automotive industry!